Condition:

New

Positioning Accuracy (mm):

0.02 mm

No. of Spindles:

Single

Working Table Size(mm):

Other

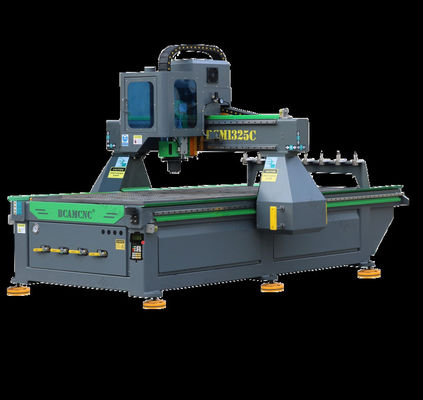

Machine Type:

CNC Router

Travel (X Axis)(mm):

1300 mm

Travel (Y Axis)(mm):

2500 mm

Repeatability (X/Y/Z) (mm):

0.02 mm

CNC or Not:

CNC

Voltage:

220V/380V

Dimension(L*W*H):

1500*3000*200mm

Power (kW):

9

Weight (KG):

2200

Warranty:

2 year

Key Selling Points:

Competitive Price

Applicable Industries:

Garment Shops, Machinery Repair Shops, Manufacturing Plant, Home Use, Retail, Construction works , Advertising Company

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

2 years

Core Components:

Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine, Gearbox

Working area:

1300*2500mm

Tool magazine:

12pcs disc/carrousel tool magazine

Control system:

Taiwan Syntec 6MA 6MB controller

Spindle:

HSD/HQD 9kw air cooling ATC spindle

Transmission:

Taiwan HIWIN 25mm guide rails, Taiwan TBI Ball Screw

Drive motor:

Japanse Yaskawa servo motor driven

Table:

vacuum adsorption + T-slot, double vacuum suction working table

Inverter:

Delta Inverter

Reducer:

Japan Shimpo reducer

Product name:

1325 carrousel ATC engraver cutting wood cnc drilling machine

Local Service Location:

None

After Warranty Service:

Video technical support, Online support, Spare parts, Field maintenance and repair service

Showroom Location:

None

Marketing Type:

New Product 2020

Certificering:

CE

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!